- Ultra-lightweight sensors can be printed directly on biological surfaces like skin and petals.

- Made from biocompatible materials, they allow seamless, non-intrusive health monitoring.

- Sensors are biodegradable, sustainable, and producible on-demand with minimal waste.

Researchers at the University of Cambridge have unveiled ultra-lightweight, eco-friendly sensors that can be directly printed onto various biological surfaces, from human skin to flower petals.

These innovative sensors are designed to be so light and imperceptible that they seamlessly integrate with the surfaces they are applied to, all while being biodegradable and easy to wash away.

Inspired by Nature

Drawing inspiration from the delicate yet strong properties of spider silk, the Cambridge team created bioelectronic fibers using a unique combination of biocompatible materials.

These materials include the conducting polymer PEDOT, hyaluronic acid, and polyethylene oxide. By utilizing an orbital spinning method, they produced fibers from a water-based solution.

Remarkably, these fibers are at least 50 times thinner than human hair, enabling them to be printed on extremely delicate surfaces, such as the fluffy seedhead of a dandelion, without causing any damage.

Seamless Integration

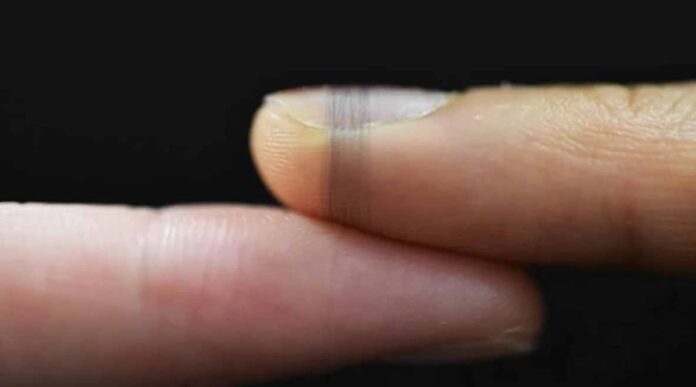

When these fibers are printed onto human skin, they conform closely to the epidermis and expose sweat pores, ensuring they are comfortable and non-intrusive.

Initial tests conducted on human fingers suggest that these sensors could revolutionize continuous health monitoring by providing more accurate and unobtrusive data collection.

Applications

According to Professor Yan Yan Shery Huang from Cambridge’s Department of Engineering, who led the research, “If you want to accurately sense anything on a biological surface like skin or a leaf, the interface between the device and the surface is vital.”

She emphasized the importance of creating bioelectronics that are completely imperceptible to the user, ensuring that they do not interfere with natural interactions and are sustainable with minimal waste.

The potential applications for this technology are vast. In healthcare, these sensors could enable more precise and non-intrusive health monitoring by continuously tracking vital signs directly from the skin. This could lead to early detection of health issues and more personalized medical care.

Additionally, the sensors could enhance electronic textiles and environmental monitoring by providing real-time data from various surfaces.

Sustainable and On-Demand Production

One of the most notable advantages of this technology is its simplicity and sustainability.

“Using our simple fabrication technique, we can put sensors almost anywhere and repair them where and when they need it, without needing a big printing machine or a centralized manufacturing facility,” said Huang.

This means that sensors can be produced on-demand, right where they are needed, reducing waste and emissions associated with traditional manufacturing processes.

Eco-Friendly Innovation

In addition to being lightweight and eco-friendly, the bioelectronic fibers are designed to be biodegradable. When they reach the end of their useful lifespan, they can simply be washed away, leaving no harmful residues behind.

This aligns with the growing emphasis on sustainable and environmentally friendly technologies in modern research and development.

The research, titled ‘Sustainable and Imperceptible Augmentation of Living Structures with Organic Bioelectronic Fibers’, has been published in the journal Nature Electronics.

This innovative work not only showcases the potential of bioelectronics but also sets the stage for future advancements in healthcare, environmental monitoring, and virtual reality.

By adopting the delicate strength of spider silk and combining it with cutting-edge materials science, the Cambridge researchers have opened up new possibilities for the seamless integration of technology into our daily lives, all while prioritizing sustainability and minimal environmental impact.